Ferro Techniek‘s thick film heating elements are custom designed to suit your application. Shape, size and electrical properties can be set and optimized for each heating job. In addition we can provide electrical connectors, thermal sensors, temperature limiters and controls. Also we are experienced in assisting in solutions for installation of thick film heaters in appliances.

Technology typical properties

· Sizes up to circular diameter180mm, or rectangular 220x155mm

· Metal base material thickness 1.0 .. 2.0mm

· Base materials: (enamel grade-) steel, or stainless steel grades 444 and 430

· Elements are suitable for class I appliances (IEC-EN60335, appliances with PE)

· Dielectric HV strength 1250VAC / 1 minute, customers may check at 1375VAC / 2 seconds max.

· Power densities up to 50W/cm2 (average over the printed area)

· Typical maximum heater service temperature 250dC (maximum temperature of heater tracks 350dC)

· Electrical connections preferred by spring loaded contacts

· Water side standard oxidized by our process. Finishing is possible

· Element assemblies may contain sensors, electrical connections, gaskets and (plastic) enclosures

Remark: Deviations from these properties may be possible upon request but may require development.

Flow Through Heater mkII

FTH mkII is an ultra fast high pressure (15bar) water flow through heater based on a thick film heating element. Water runs at high speed along a channel over the heater. This results in hot water in just seconds. FTH mkII delivers water up to boiling temperature and can even create steam! The heater will fastly improve the sustainablity of your application. This is confirmed by this LCA, conducted by TNO.

Features:

- Heat up temperature to 100°C, in just seconds!

- Instant hot water! No water storage!

- No standby mode required / low energy consumption

- Integrated temperature sensing (NTC) and thermal protection (E-Fast)

- Prepared for electronic volume measurement

- Suitable for steam generation

- Friendly with regards to lime scale forming and easy to descale

- Compact design

- Food safe materials / full stainless steel water channel

Specifications *

- Power range: 1000W – 2300W / 230VAC and 1000W – 1800W / 120VAC (UL)

- Element power: single or dual sections (power ratio approx. 2:1)

- Dimensions (W x L x H) : 90mm x 120mm x 40mm

- Flow rate: max. 12 ml/s (pressure drop <1 bar)

- Max. operating pressure: 20 bar, burst pressure : 40 bar

- Outlet NTC sensor: Fast response, 50kΩ @25°C, ß25/80=3976K

- Water connections for low pressure hoses: barbed fitting for ø5mm tube

- Water connections for high pressure application: fitting to 4x2mm Teflon tube

- Electrical connections heater: L, N, PE, E-Fast – 4,8mm x 0,8mm terminals

- Electrical connections NTC: JST XH-series 2-pole

- Overheat protection: E-Fast, NTC, thermal fuse

- Time constant heating: <5 seconds

- Options:

- Thermal fuse set

- Electronic control module (outlet temperature, overheating protection, dispensed volume)

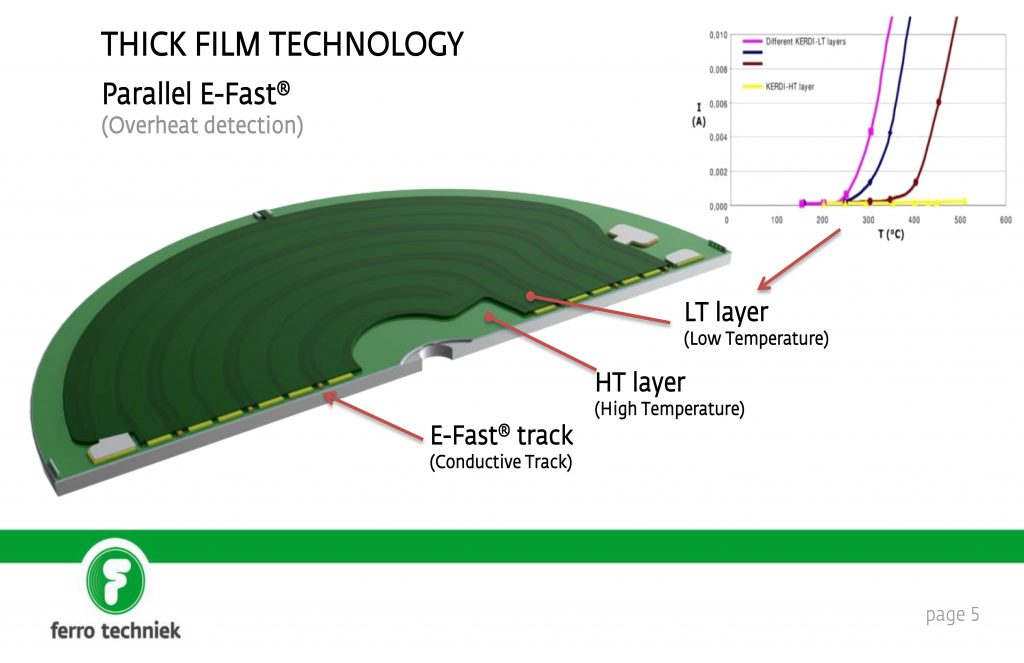

E-Fast Technology

* Deviations from these specifications upon request